“Deep cleaning” in the mountain

22.03.2017 — RHI AG, a world leader in high-quality industrial fireproof products mines magnesite at three sites in Austria including Breitenau in Styria. Dussmann Service has been contracted with cleaning services. One cleaning operative actually cleans below ground. Our author joined her underground.

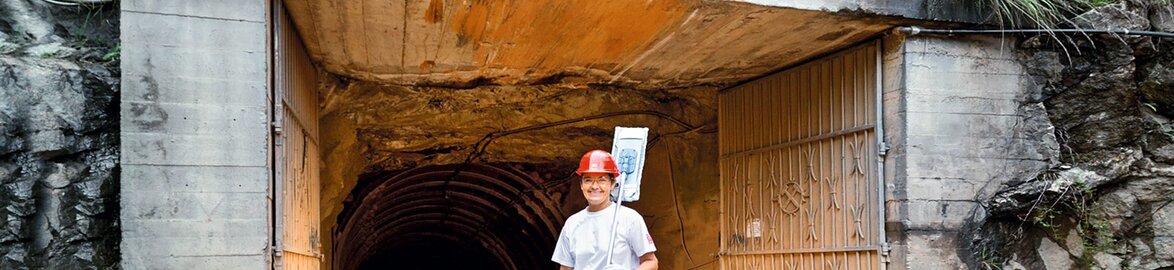

Karin Gmundner packs cleaning materials into the van and sits next to me on the back seat. At the wheel is an RHI employee. After a short drive through the woods, we pass the mine entrance. The traditional miners’ greeting “Glück auf! ” is written in large letters on a sign hanging above. A few moments later, we are surrounded by darkness, broken only by the beams from the van’s headlamps. The journey continues at speed along a steep, bumpy road that winds deeply into the mountain. Suddenly, we see a light moving towards us— a transporter is making its way to the surface carrying 35 tons of magnesite ore. We stop in front of a container which is used by the miners as a break room. The air around us is warm and humid. Karin Gmundner carries her cleaning equipment in. She has to bring everything that she needs to do her work with her into the mine, including water. Despite the deployment of machines, the miners’ work is strenuous and regular breaks are important. Containers, which are placed at two different levels, provide them with a comfortable, clean environment to relax. We proceed to the second container which is only 300 meters above sea level.

After two hours underground, we return to the surface. Karin Gmundner seems unimpressed by the “journey to hell” whilst my blood pressure is only slowly returning to normal. “It took a while to get used to” she recalls “but I have never felt dizzy and the trepidation that l felt at the beginning soon disappeared.” Following extensive training for the specific tasks involved in this industrial cleaning operation, Karin Gmundner has been coming to the mine once a week for nine years. “It’s a change and rather unusual. I like that. When I talk about my work, it always amazes people” she laughs.

We drive on to the RHI industrial plant in Breitenau where the around 400,000 tons of magnesite ore which is blasted from the mountain each year is processed into fire-proof products. These are used to line steel pans and cement rotary kilns so that they can withstand extreme temperatures of over 1,200 degrees Celsius.

Long contractual period = win-win Situation

Dussmann Service operatives clean the industrial plant each day in two shifts including offices, kitchens, staircases and sanitary facilities. It is inevitable that metal dust and other dirt is carried in from the workshops and kilns of the industrial processes. Efficient cleaning is key, indeed the objective of the first tender of maintenance cleaning services for eight years in 2012 was to increase efficiency. RHI AG operates at seven locations in Austria which were served by various service providers including Dussmann Service who commenced operation in 1995. The tender aimed to reduce the number of service providers and to update the service specification. Together with 20 competitors, Dussmann Service participated in the tender and won the contract for all Austrian locations except Vienna. The contract is for five years—a period that is not common but it enables the Dussmann team to familiarize itself with local conditions and the client benefits from cost savings.

A single employee is responsible for coordination of cleaning operations at all six RHI locations. The clearly defined cleaning services facilitate efficient work and the satisfaction of RHI employees with the standard of cleaning has significantly improved. The Dussmann team too are happy with their working environment, both above and below ground as demonstrated by staff turnover statistics; not only Karin Gmundner but many of her colleagues have been team members for many years.

Dussmann Newsroom

News

News, stories, downloads and images - everything about Dussmann and the business units Facility Management, Food Services and Technical Solutions can be found in the Newsroom. Take a look and get to know us better!